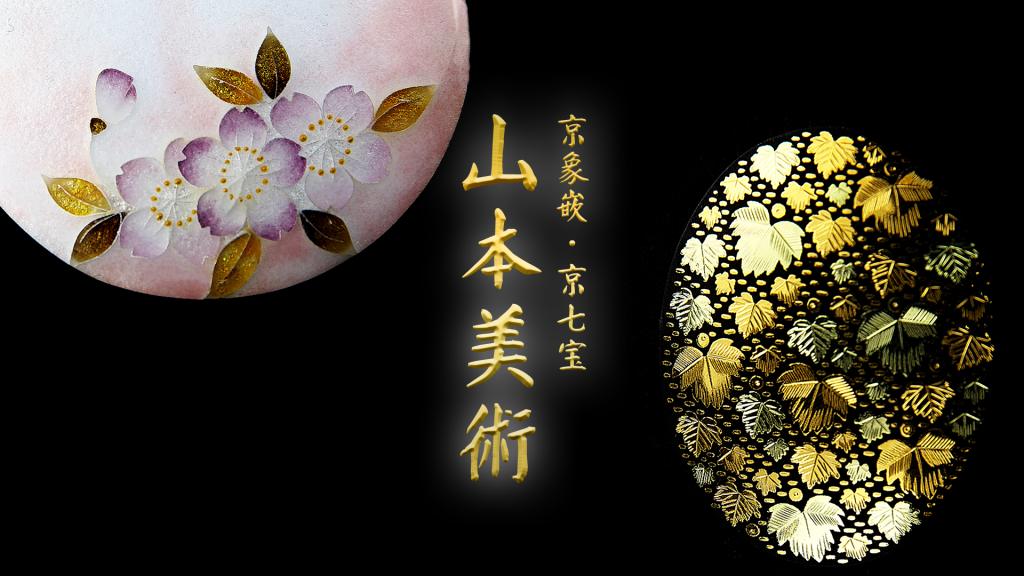

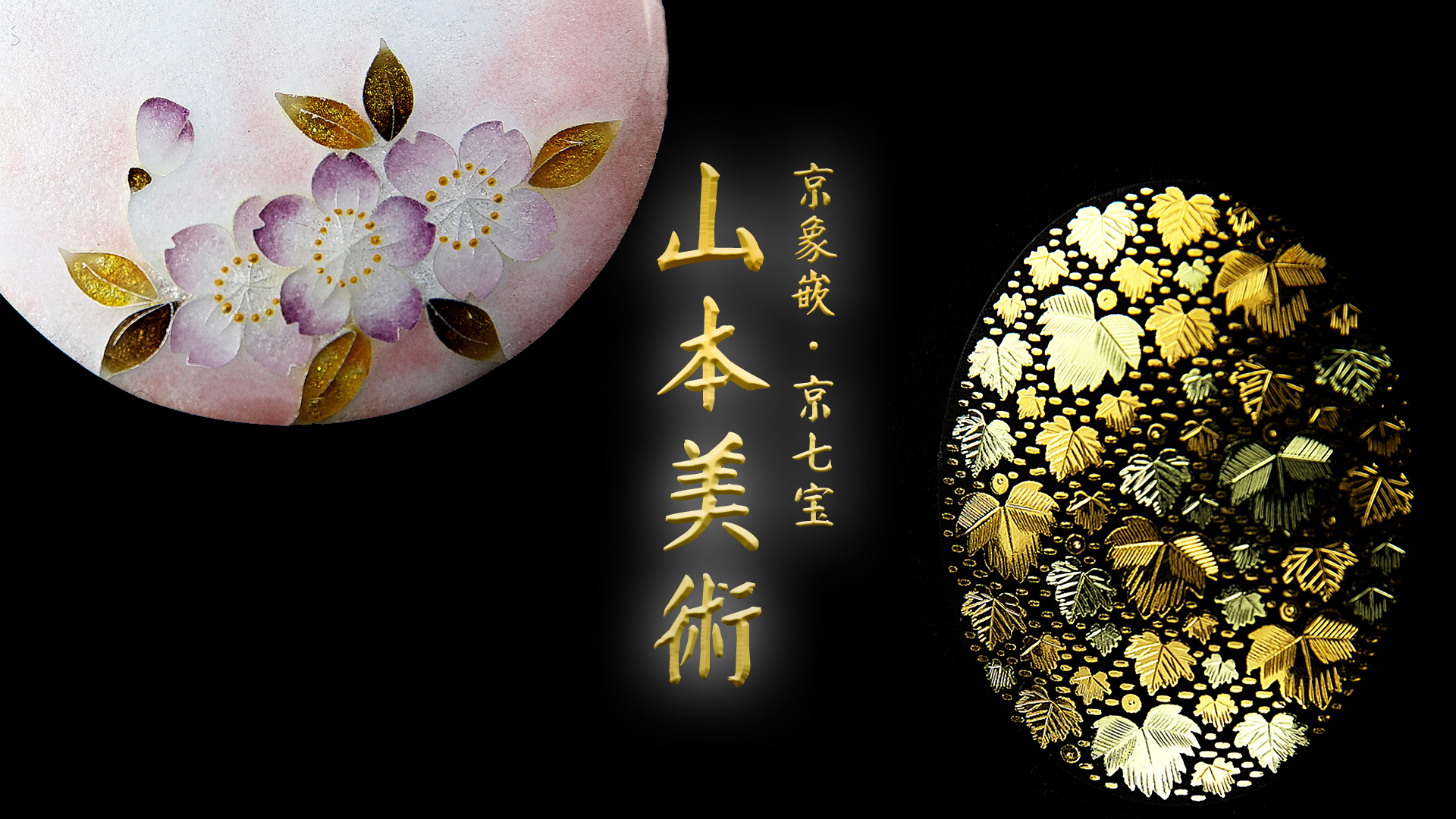

京象嵌・京七宝の山本美術

山本美術

山本美術のホームページをご覧いただき、ありがとうございます。 山本美術では、京都の伝統工芸である、京象嵌、京七宝の技術をベースに、オリジナル象嵌・七宝・七宝入り象嵌・各種バッチ・各種アクセサリー等の企画・製造・卸を行っています。一品の製作から、注文生産、量産まで対応いたします。

Thanks for coming to the homepage of Yamamoto Bijutsu corp. Yamamoto Bijutu are making traditional crafts, Kyou-Zogan (damascene made in Kyoto) and Kyou-Shippou (cloisonne made in Kyoto). ※Damascene also known as a inlay.

top picture ©watomos